Understanding Packaging Machines: A Guide for B2B Businesses

Packaging machines are among the most important in today’s manufacturing and food processing industries. These machines are thus programmed to meet the purpose of packing or enclosing, in proper containers, various types of products, in various forms and with the right standard of commercial acceptability. In this article, we will look at some of the types of packaging machines that are available on the market and how they will benefit your business line.

What are Packaging Machines

Packaging machines are machinery used in the packaging of products of various forms including bottles, canning carries, pouches and other carry packs or even boxes. Their function is to automate packaging operations, minimize workers’ expenses, and produce uniform packaging designs for storage, transport, and display. The equipment used in packaging depends on the type of industry and the kind of material used in packaging and it may include plastic, glass, metal and paper among others.

Whenever there is this kind of packaging need, flows and requirements arising, there are innovative manufacturers such as Levapack who always come up with new products to fit in this need in the market for efficient packaged systems. Explore packaging machines from Levapack here https://www.levapack.com/fr/product-category/canning-lines/.

Packaging Machines Categories

These packaging machines are available in different forms, depending on packaging needs of an item. Below are some common types:

-

Filling Machines

Filling machines on the other hand are packaging machines that are used to fill packaging containers with liquid, powders or granules. These machines are suitable for handling large numbers of products and are applied mostly in (FOOD & BEVERAGE), PHARMACEUTICALS & COSMETICS sectors.

-

Sealing Machines

Other machinery involves sealing machines which are used to seal the filled containers so as to assure they are properly sealed and cannot be opened. Such machines can heat-seal bottles, cans and pouches or apply pressure seal or heat seal for packing your products.

-

Labeling Machines

An example of packaging application is where label applying equipment puts labels on to the products or on their containers. It can contain barcodes, information about the product, or brands. They are useful in lines of businesses that require product recognition and conformity to certain standards.

-

Wrapping Machines

A wrapping machine therefore encompasses a device that is used for wrapping a particular product or container with a plastic film, stretch film or any other type of wrapping material. This is particularly beneficial where the product to be labelled is round items such as bottles, cans and so on.

-

Cartoning Machines

Casing equipment has the function of packaging articles within cartons for dispatch or retailing,cartoning machinery. These machines are generally employed in consumer products, drug & pharmaceuticals and food packing industries.

These packaging machines vary in their function so the packaging line is composed of a series of specialized packaging machines that can meet packaging requirements of high production output.

Advantages of Using Automated Packaging Machines

For B2B businesses, investing in automated packaging solutions like those offered by Levapack can bring several key advantages:

Increased Efficiency

Among the advantages of package making machines, there is one widely known and quite obvious – the speed of work. From this, it is clear that the use of some automated systems can do packaging tasks much faster than employing manual labor in terms of time taken and production rate.

Consistency and Quality

Package machines on the other hand guarantee quality in each pack. This also minimizes the involvement of man in the packaging of products hence can package the products to a particular standard. In areas of food, pharmaceutical’s, consistency is very important for compliance purposes and also to serve customers.

Cost Reduction

Admittedly, it may require a large investment in conducting packaging machines, but all the same, in the long run, they are cost-effective. When repetitive tasks are assigned to business entities, the demand for manpower is less felt, vice and waste is avoided, and efficiency is increased.

Flexibility

Most packaging machines used in modern facilities are versatile and can be quickly reconfigured to accommodate different packaging types, product dimensions and material. As a result it can easily adapt to changes in demand or in some other market circumstances.

How to Choose the Right Packaging Machine

The determinant factors that influence packaging machine selection include the following. Businesses should consider the following:

Product Type

As it has been established that various products demand different packaging methods, the next part explains the. For instance, liquids might necessitate the use of filling and sealing equipment, while solid products may…”;

9 For instance, liquids may necessitate the use of filling and sealing equipment, while solid products may…

For example, liquids may require filling and sealing machines, while solid products may need labeling and cartoning machines. You should also know about your product’s special needs if you intend to select the right equipment.

Production Volume

Production quantity is another important attribute A major determinant is the volume of production. Large production volumes need machines that are more extensive, faster, and of higher output, than machines used in small production volumes which may incorporate a lot of hand work.

Budget

Of equal importance is the usage of budget as a knowledge source. Nevertheless, advanced packaging machines, which can perform high, flexible outputs are available with high costs. Businesses risk losing potential cost savings and increased efficiency in operations as well as overall organization productivity to their initial costs.

Machine Features

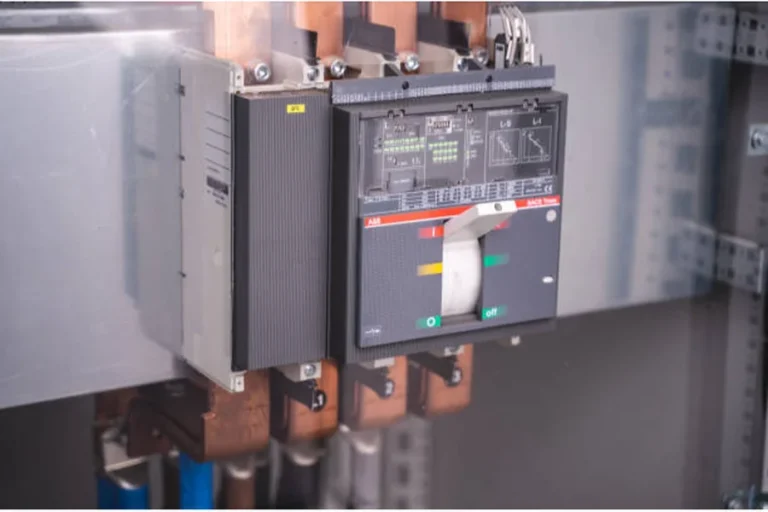

Some of the characteristics may include; the velocity of the machine, how easy it is to operate, how frequently it needs to be serviced among other factors of the packaging type that the machine offers. Most machines used today are equipped with automatic control and remote interfaces, as well as modularity for connection to other production lines.

The Future of Packaging Machines

The packaging machine industry undergoes a process of continuous development at present. With dynamic and evolving consumers and purchases, packaging machines are cascading to evolutions in technology. As we go forward into the future there will be even more reliance on automation, better machines, and design to fit the needs of different industries.

The use of intelligent packaging machines for instance enables increased accuracy, constant checking and even fixing from a distance. Moreover, there is a tendency to extend the life cycle and improve energy efficiency, many producers are engaged in developing devices and using environmentally friendly materials.

The authors are of the opinion that packaging machines will be used more frequently in industries with high demand for high quality products. These improvements can be implemented in order to make organizations remain relevant to the market thereby fulfilling new requirements.

Therefore, for most B2B businesses who are seeking to advance their packaging, integrating automatic packaging equipment is the way to go. Newly developed packaging machines are applicable for any industry no matter whether it is food and beverage, pharmaceutical or the consumer goods industry as the use of packaging machines has numerous advantages like improved efficiency and thereby also minimized costs and an enhanced quality of the products. This explains why choosing the right machine should always be considered while at the same time adopting the relevant technological innovations to enhance operations as firms continue to form in the dynamically competitive world.